Hydraulic bending machines/hydraulic press brake can be divided according to the synchronization method: hydraulic Synchronous torque bending machine , CNC press brake and electro-hydraulic cnc press brake And can be divided into the following types of movement: upward-acting, downward-acting.

Press brake bending requires different methods of approach to achieve the desired results needed. From forming wind tower poles to intricate electrical cabinet components, press brakes are a vital tool for the fabricator and knowing that not all bending is the same is a key to the successful operation of them. Understanding the process, the tooling and the material (as all metals being bent will respond differently to each bending process) is vital to gaining accurate parts quickly and repeatedly.

hydraulic Synchronous torque bending machine/ hydraulic Synchronous torque press brake

Double cylinders control slider up and down movement

Mechanical torque synchronization

CNC press brake and electro-hydraulic press brake

CNC Press Brakes: these types of brakes have the highest precision and customization abilities, utilizing computer technology to control accuracy and increase efficiency. When using CNC brake presses, data such as bending angle, plate thickness, width, and grade are entered into a controller by a trained operator and the brake easily handles the rest.

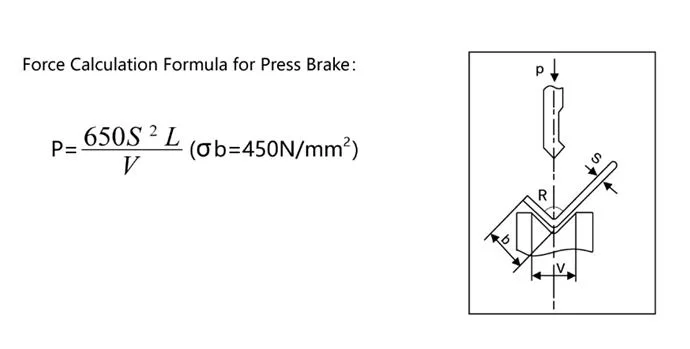

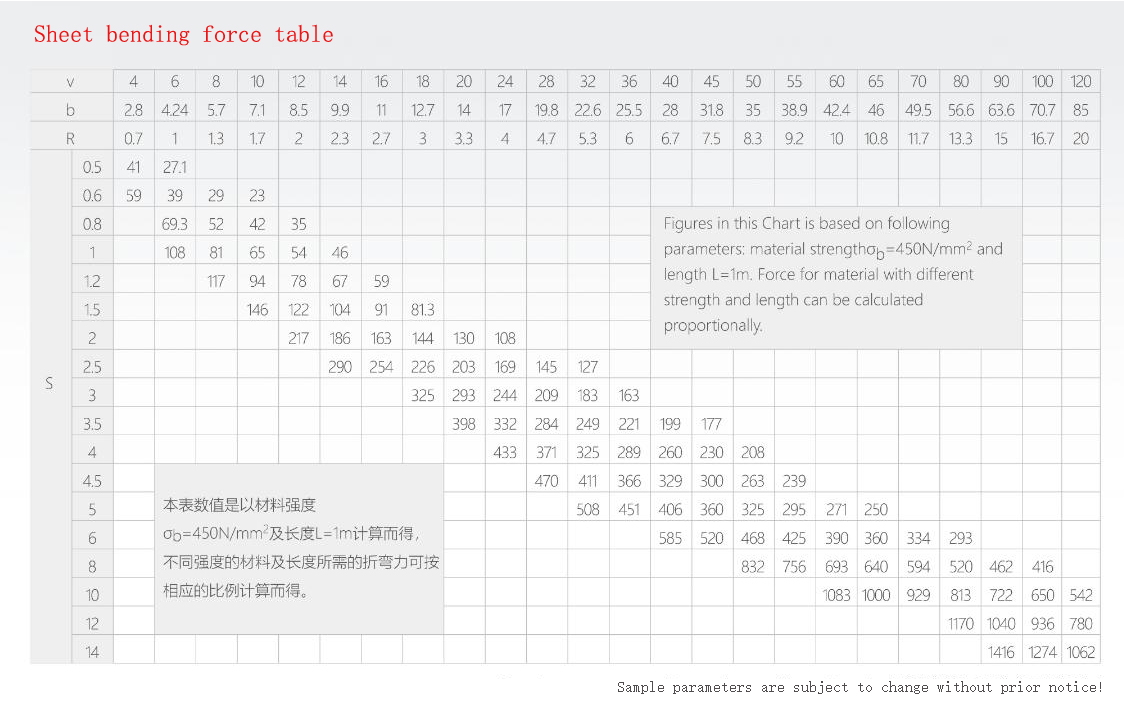

How to calculate press brake tonnage

During the bending process, the force between the upper and lower dies is applied to the material, causing the material to undergo plastic deformation. The working tonnage refers to the exaggeration pressure when the sound is folded. The influencing factors for determining the working tonnage are: bending radius, bending method, die ratio, elbow length, thickness and strength of the bending material, etc.

Press brake forming tonnage calculations are relatively easy. The trick is knowing where, when, and how to apply them. Let’s begin with the tonnage calculation, which is based on the point where the yield is broken in the material and actual bending begins. The formula is based on AISI 1035 cold-rolled steel with 60,000-PSI tensile strength. That’s our baseline material. The basic formula is as follows:

P: Bending force (kn)

S:plate thickness (mm)

L:plate width (m)

V:bottom die slot width (mm)

Example 1:

S=4mm L=1000mm V=32mm, look up the table and get P=330kN

2. This table is calculated on the basis of materials with strength Оb=450N/mm2. When bending other different materials, the bending pressure is the product of the data in the table and the following coefficients;

Bronze (soft): 0.5; stainless steel: 1.5; aluminum (soft): 0.5; chromium molybdenum steel: 2.0.

Approximate calculation formula for bending pressure: P=650s2L/1000v

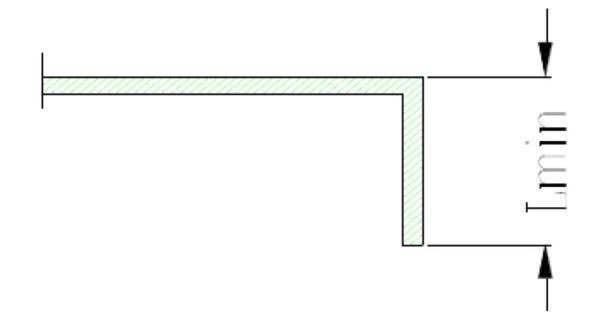

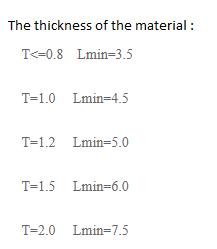

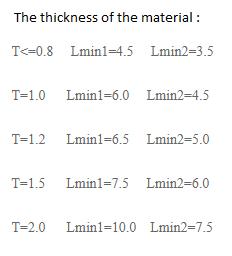

The size of the smallest bend:

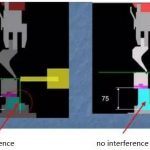

A. Sngle folding /bending :

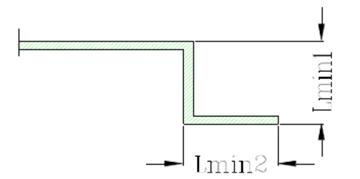

B. Bending /folidng Z

Example 2:

Plate thickness S=4mm, width L=3m, ob=450N/mm2

Generally slot width V=S*8 Therefore P=650423/4*8=975(KN)= 99.5 (Ton)

The result is very close to the data in the bending force chart.

As you can see, method #1 to calculate the press brake tonnage is based on the mild steel material.

What if the material is stainless steel, aluminum or brass?

lt's simple, multiply the results calculated by the above formula by the coefficients in the following table:

| مواد | Coefficients |

| Mild steel | 1 |

| Stainless steel | 1.6 |

| المونیم | 0.65 |

| Brass | 0.5 |